Take out the model and place it on an even surface. Clean the model with air jet to remove unbound white dust around the model.ġ6. Connect the vacuum adapter to the compressor.ġ5. Carefully take the model to the ZD5 Depowdering System machine. Carefully take out the output model since the model is very fragile.ġ4. The following window shows and the print starts.ġ3. (Cross check and tick all the options.)ġ2. The final window appears as “Last check before printing”. The following pop up appears for printing options. (It varies as per the volume of model)ġ0. Under ‘Transform’ tab we can rotate and reset the position/orientation of the model as per requirement.ĩ. The Z printer automatically places the model in the workable volume. Set the units as mm or as per the Rhino model.Ĩ.

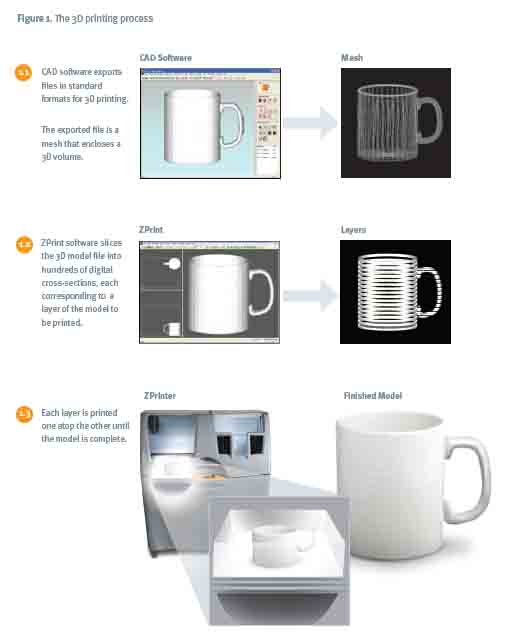

ZPRINT 3D PRINTER SOFTWARE

Open the STL file in Z Print software in the workshop.ħ. After closing the cover, switch the printer to ‘Online’.Ħ. Put the required powder as per model size. Set up the Spectrum Z510 machine in the laboratory.Ī. Click Preview to check the smoothness of the surface. Set Tolerance as ‘ 0.05mm’ (Default as 0.01mm) (It depends on required accuracy/smoothness of the output.). Save as type ‘ Stereolithography (*.stl)’ģ. It should not have any naked ends or open ends.Ģ. You can also set the polygon density for the finished output.ġ.Check for the consistency in the model in the “diagnostics” and “edge tools” under the Analyze tab. We now mesh the polysurface using “from NURBS Object” under the Mesh tab. Make sure the polysurface is a closed polysurface to process the model in the 3D printer. The printer can print to a precision of 0.5mm but but to give strength to the output sample it is recommended that minimum thicknesses not be less than 2 – 3mm.Ġ. Model: Spectrum Z510, ZD5 Depowdering System

0 kommentar(er)

0 kommentar(er)